”Urban πLOT” is a software and hardware solution based on an innovative mathematical model of metro train movement. This complex uses present-day developments in the rolling equipment microprocessor control system area.

Key features:

- power saving control modes can be estimated and implemented in real-time mode, using track grading as well as thrust control and all kinds of train brake control;

- extensive radio communication between the train and OCC is not required;

- the driver has the possibility to choose the train control mode;

- independence from the operation control center is reached by means of start upload of track grading data for thrust-brake optimum point calculation;

- train control automation is intended to control human factor.

The system provides train traffic control meeting the requirements of safety standards.

How it works

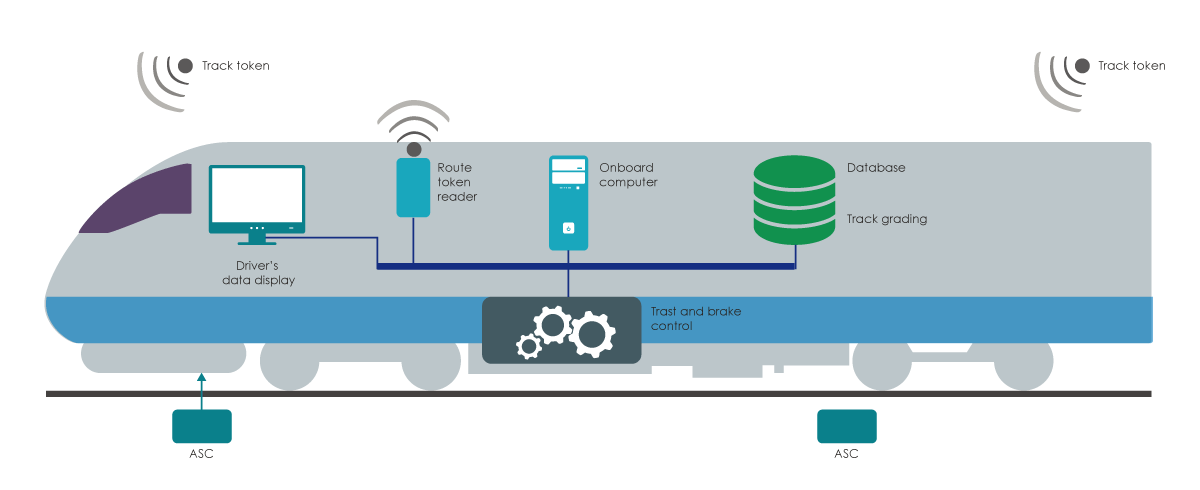

Track token set provides exact train coordinate location to the route. Each track token has its own ID, which is read by the train reader.

Track token reader transmits this information to the onboard computer and fixes transmitted signal from the track token. Then, onboard computer defines energy optimal train motion path in the actual route point and chooses the required adapted thrust control modes and brake system modes according to the received data.

To define an optimum train control mode, the program uses multimedia information about:

- current train condition ( using information from the train circuits);

- train load

- speed limitation data, taking into account track grading as well as infrastructure position data. Data is transmitted to the onboard computer through the automatic speed control system and is set in start conditions.

Recorded dynamic behavior, train traffic and automatic operation parameters are shown on the driver’s data display.

System safety attains by means of its coordination with automatic speed control operating subsystem.

Advantages of the system implementation

The implementation of automatic train operation system allows:

- to decrease power consumption by means of accelerate-decelerate process optimization;

- to provide optimum train control mode and decrease braking time at the platforms;

- to decrease the wear-out of rolling equipment by means of critical traction and braking condition exclusion as well as by improving the control;

- to increase traffic safety by means of:

- exact following the speed rate both on traffic light signals and in speed limitation areas, including temporary ones;

- minimizing the human factor;

- to improve passengers service quality.